Complex

Developing customized solutions is our strong point.

We combine experience and know-how with an aspiration to develop solutions to the highest standards of engineering and economic efficiency. Avail yourself of our high flexibility and capability – from consultation through planning to designing, manufacturing and commissioning – both for individual pieces and for end-to-end solutions.

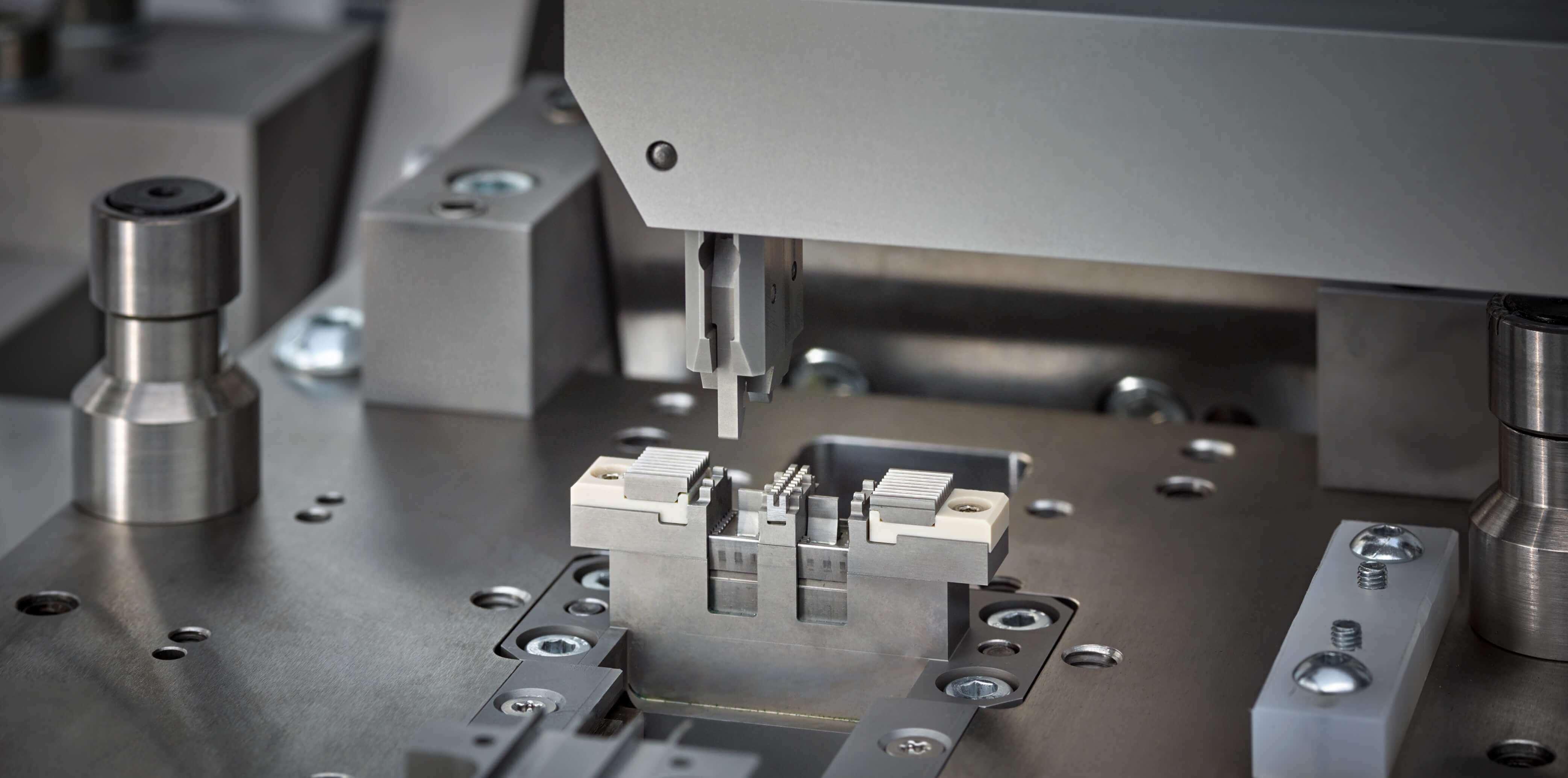

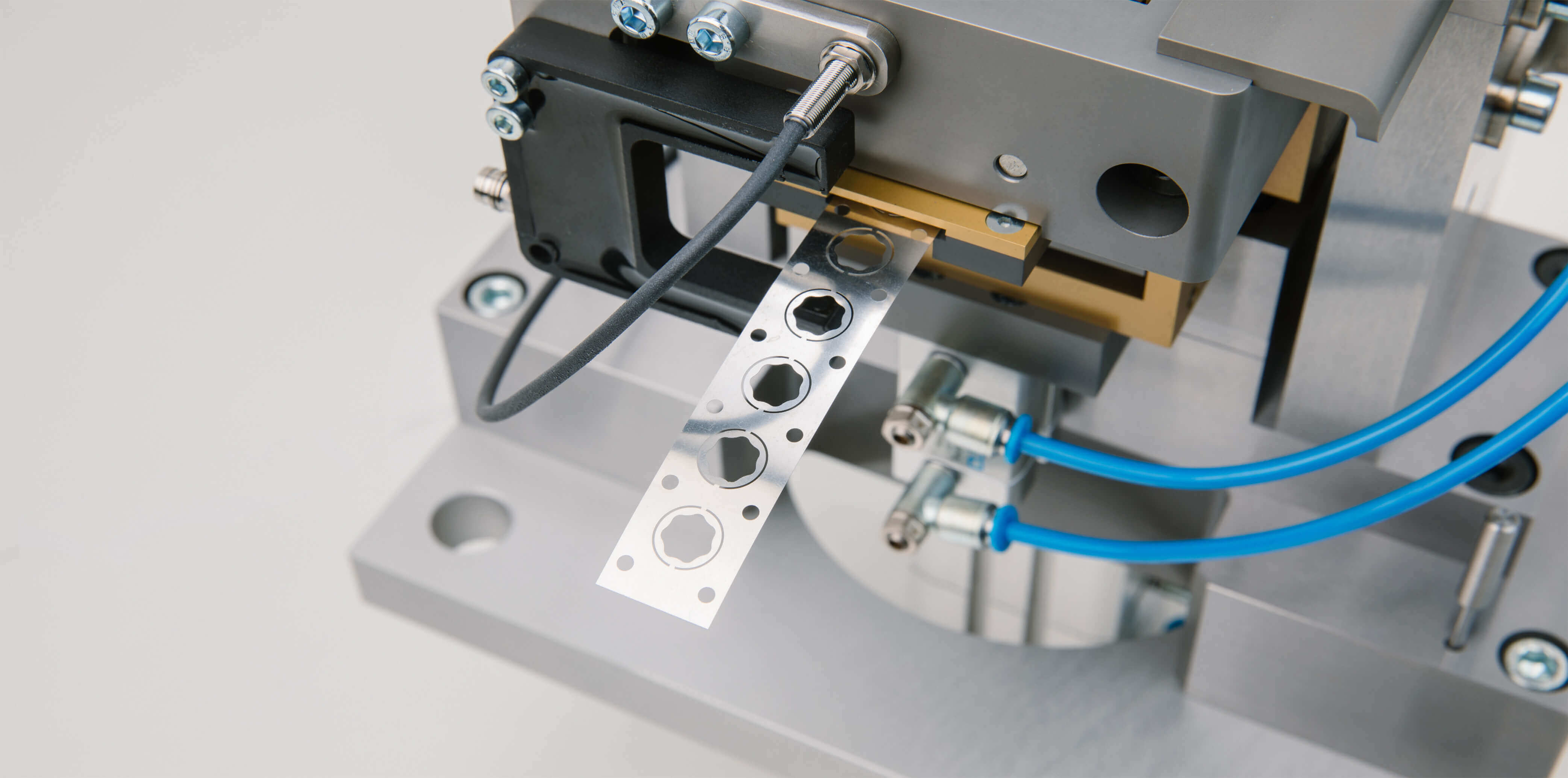

The range of products we develop and manufacture includes bending units, cutting and forming tools for use on a wide variety of materials and at manual workplaces, as well as special machines, devices, subassemblies, robot grippers and workpiece holders.

Precise

We guarantee for reliable quality.

Making workpieces to the tightest tolerances and top surface quality is our strong point.

Operated in outstanding working conditions in fully air-conditioned and vibration-cushioned production facilities, our high-end machines have reached tolerances below one µ. Our products come with our own measuring protocols or with calibration certificates from accredited companies as required.

Compact

Make use of our competence in dealing with extremely small workpieces and geometries.

Even the tiniest and most delicate components can be cut corrosion-free in oil and measured without touching. As we use a wide variety of technologies – from wire-cut EDM and die-sink EDM, flat and cylindrical grinding, five-axis abreast milling to 3D-printing of aluminium, steel, stainless steel and titanium – there is hardly a limit to the smallness and intricacy of the geometries you may require.

Innovative

We execute the additive manufacture of your components – from first idea to success.

Additive manufacturing is used where subtractive methods are not sufficient. Geometries formerly “impossible” – including cavities, undercuts and complex internal structures - can now become reality. In a high-purity argon atmosphere we “print” components in aluminium, stainless steel and tool steel with excellent material and component quality. Using the powder-bed method we generate complex structures with hardly a limit to geometry. The completely finished components we produce for you are optimized in terms of functionality, size and weight. We offer all technological steps of manufacturing and finishing, including the complete portfolio from design to inspection protocol or CT qualification.

Contact

Schulze Werkzeugbau GmbH & Co. KG

Am Eichelberg 2

01458 Ottendorf-Okrilla

Germany

Phone +49 35205 . 756 300

Fax +49 35205 . 756 308

info@schulze-werkzeugbau.de

Opening Hours

Monday - Friday

8AM - 4PM

and on appointment